Table Of Content

An important component in supply chain design is determining how an effective supply chain design is achieved, given a performance measure, or a set of performance measures. Research in supply chain modeling has only scratched the surface of how supply chain strategies (or decision variables) may affect a given performance measure, or a set of performance measures. Pyke and Cohen (1994) follow Pyke and Cohen (1993) research by including a more complicated production network. In Pyke and Cohen (1994), the authors again consider an integrated supply chain with one manufacturing facility, one warehouse, and one retailer, but now consider multiple product types. The new model yields similar outputs; however, it determines the key decision variables for each product type. Research has shown that decisions taken during the design stage have a considerable effect on agility, customisation strategies, supply chain and product life costs.

What’s the difference between value chains and supply chains?

For example, designing a product with fewer components leads to shorter aggregate lead times. Sustainability is increasingly integral to supply chain network design as businesses recognize the environmental and social impacts of their operations. In this context, sustainability refers to minimizing the carbon footprint, reducing waste, and considering social responsibility in the design and operation of supply chains.

Customer integration

Optilogic to Host OptiCon 2023: The Supply Chain Network Design Event of the Year PRUnderground - PR Underground

Optilogic to Host OptiCon 2023: The Supply Chain Network Design Event of the Year PRUnderground.

Posted: Thu, 18 May 2023 07:00:00 GMT [source]

An amazing experience to learn and explore supply chain design from theoretical background all the way to an actual application and hands-on experience with interactive visual interfaces and simulations. Fully recommended to anyone with the need to understand supply chain better. Our online courses take place asynchronously over several weeks or months using a comprehensive menu of materials from the MITx MicroMasters® Program in Supply Chain Management or custom content created for companies. We curate lesson plans with the organization and augment learning with live synchronous online events.

Why Is Effective Communication Important In The Workplace? Top 10 Tips To Improve It

The company must locate its facilities to ensure prompt delivery of goods to the customer at the lowest cost. It must also look at its suppliers’ locations before designing the supply chain. Other factors include regulatory requirements, infrastructure availability, and other utilities. Companies must also look at the availability of a skilled workforce when deciding on the production facility. Transportation is another element that influences the creation of supply chain design.

Navigating the Intricacies of Supply Chain Design in Logistics - Times Now

Navigating the Intricacies of Supply Chain Design in Logistics.

Posted: Thu, 04 Jan 2024 08:00:00 GMT [source]

Shift Left for supply chain success: dive deep with Siemens Digital Logistics at Gartner

Ethics has become an increasingly important aspect of supply chain management, so much so that a set of principles called supply chain ethics was born. Many investors today want to know how companies produce their products, treat their workforce, and protect the environment. As a result, companies respond by instituting measures to reduce waste, improve working conditions, and lessen their impact on the environment—all of which can involve SCM.

What Is Supply Chain Management vs. Business Logistics Management?

When sourcing goods, companies should be mindful of lead times and how well equipped a supplier is to meet their needs. Typically, SCM attempts to centrally control or link the production, shipment, and distribution of a product. By managing the supply chain, companies can cut excess costs and needless steps and deliver products to the consumer faster. This is done by keeping tighter control of internal inventories, internal production, distribution, sales, and the inventories of company vendors. Table 1 identifies the performance measures that have been used in the literature. These measures and others may be appropriate for supply chain design and analysis.

Cosmic Frog lets you connect to external data and create dashboards representing your unique metrics and KPIs. You can connect the organization much more efficiently and accurately than legacy technology. Design, planning, and visibility should be working synchronously, and that’s what Optilogic accomplishes with Cosmic Frog. Because Cosmic Frog is cloud-native, the platform makes it easy to collaborate on data and the outputs of these models, both internally and externally if you’re working with consulting partners and suppliers. Models and metrics are easily updated, and you have visibility to define what works on a quarter-by-quarter basis. The models reviewed here, and summarized above in Table 1, utilize a number of the performance measures identified in Sections 4.1 and 4.2.

In supply chain modeling, there are a number of issues that are receiving increasing attention, as evidenced by their prevalent consideration in the work reviewed here. That is, the actual variance and magnitude of the orders at each echelon is increasingly higher than the variance and magnitude of the sales, and that this phenomenon propagates upstream within the chain. The problem is to determine a step P such that steps 1 through P will be performed at the factory and steps (P+1) to I will be performed at the DCs.

Few established companies have fully digitized their end-to-end operations. But digitization can be a feasible solution to operational challenges seen across many companies and industries. Industry 4.0, or the Fourth Industrial Revolution (4IR), describes the impact that increased connectivity, automation, and more have had on technology, industry, and society. A supply chain is made up of interconnected parts of a whole, all of which add up to finished products bought by customers. The ore is transported to a plant, where it’s turned into steel, which is made into the chassis of the automobile.

A long drawn-out transition strategy places an unnecessary burden on the chain to maintain inventory, service levels and supply of older components. This includes evaluating lead times, transportation costs, and potential disruptions. Once a baseline has been established in supply chain network design, running different scenarios becomes a powerful tool for decision-makers. This process involves simulating various hypothetical situations to assess the potential impact of changes or events on the supply chain. Whether it is adjusting inventory levels, changing distribution strategies, or modifying transportation routes, having a baseline helps in understanding the deviations from the current state.

It relaunched a full transformation and change program, designing a new blueprint for its overall supply chain while protecting business units’ independence in execution. Although the COVID-19 pandemic has delivered the biggest supply chain or value chain shock in recent memory, other examples abound. The Russian invasion of Ukraine has led to the worst humanitarian crisis in Europe since World War II, as well as supply chain disruptions in critical sectors, including agriculture, automotive, energy, and food. Changes in the environment and global economy have increased the frequency and magnitude of these shocks. These experts will unveil insights into procurement optimisation, sustainability, diversity, and risk resilience, among other pivotal topics shaping the future of our industries.

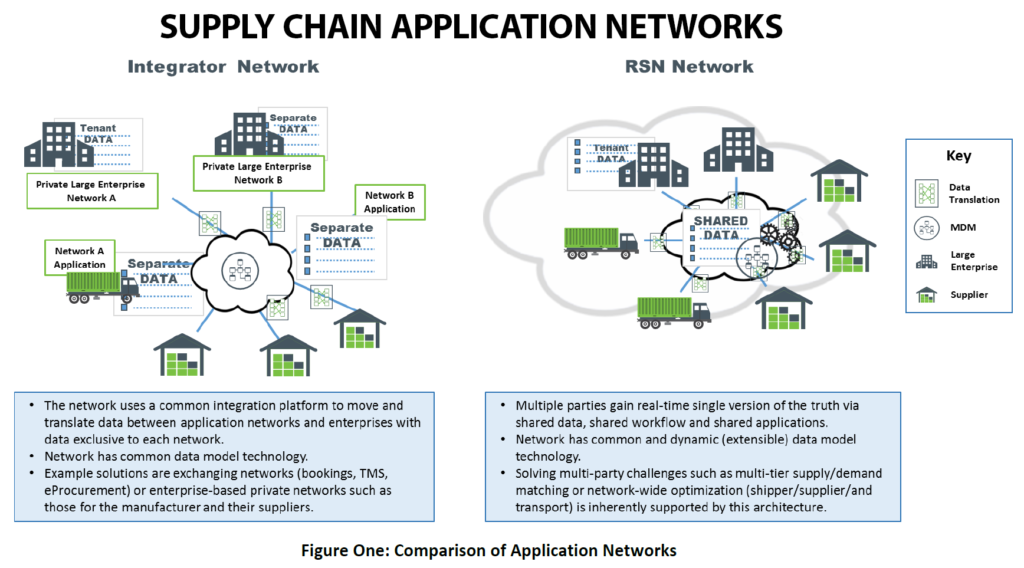

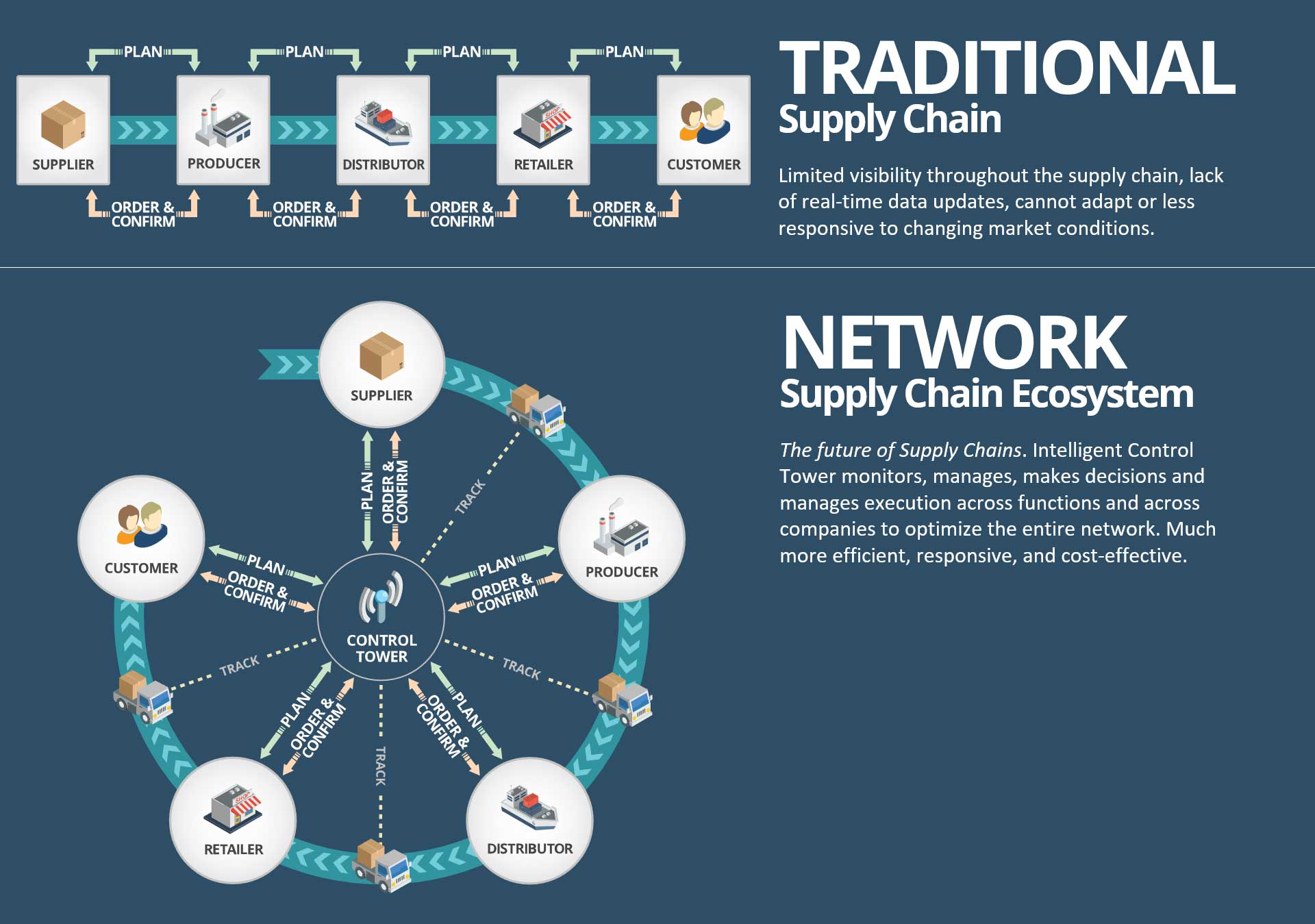

These Processes illustrated below in Figure 1, provide the basic framework for the conversion and movement of raw materials into final products. This chain is traditionally characterized by a forward flow of materials and a backward flow of information. For years, researchers and practitioners have primarily investigated the various processes of the supply chain individually. Recently, however, there has been increasing attention placed on the performance, design, and analysis of the supply chain as a whole. For years, researchers and practitioners have primarily investigated the various processes within manufacturing supply chains individually. The above example shows that a design team’s familiarity with the product’s supply chain processes can enable them to create designs that sync better with the supply chain management.

All the companies making similar products compete for the same set of customers. In this market, the users are not very much concerned about minor product differences between different competitors. What is most important in this supply chain design is that the company must be able to use its machinery to its maximum capacity. They must ensure the optimum efficiency of all assets for a reduced cost.

No comments:

Post a Comment